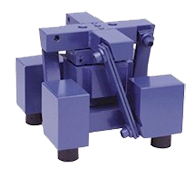

Supply Hoppers for Feeding Parts/Materials to Vibratory and Centrifugal Parts Handling Systems

Supply hoppers are amongst the popular automation machine we at Vibratory Feeders, Inc. (VFI) offer. They are known for their precise designs, sturdy constructions, and trouble free performance. They are exclusively designed to load parts into a vibratory bowl feeding system automatically. They support several product manufacturing industries to automate their production lines. These bulk supply hoppers keep vibratory and centrifugal parts handling systems running at high efficiency.

Store and Sort a Wide Range of Materials

Being a customer centric organization, we aim to provide performance driven bulk supply hoppers in various sizes, shapes, and configurations. We offer:

- Standard Hoppers – They are ideal for feeding lightweight parts; the weight should not exceed to 40 pounds.

- Straight-front Hoppers– These types of supply hoppers feature straight-front, larger bin opening and wider tray. They are largely chosen for feeding parts around three inches long.

- Low Profile Hoppers - These hoppers are characterized by their larger footprints and lower loading heights. Manufactured from mild and 304 stainless steel, they are largely preferred for corrosion prone industrial environments.

Apart from these standard designs, we also offer specialized bulk feeders and hopper elevators. These hoppers are perfect for feeding larger and heavier parts. These floor mounted hoppers are designed with a belt conveyor to lift parts into the feeder bowl from a low loading height. They are available in 5 to 20 cu. ft. capacities.

We can also customize supply hoppers according to your specifications. Let us know your application requirements. We will suggest the right supply hopper model from our standard inventory, or will custom make one for you per your application requirements.

Why must you Invest in Vibratory Feeders Bulk Supply Hoppers?

Our supply hoppers are one of the most valuable investments, adding value to your parts feeding applications. The reasons that account for the wide popularity and acceptance of our bulk hoppers are:

- They are designed to operate by means of non-contact level control devices. This eliminates the need of any kind of labor force to manage the operation. This in turn brings huge savings of time, and labor cost.

- They are versatile and cost-effective systems, designed to feed parts in mass quantities.

- They are designed to gently convey awkwardly-shaped bulk parts without causing any damage.

Heavy Duty Construction

Taking into consideration the harsh conditions in industrial environments in mind, our hoppers are manufactured using quality tested raw materials. The parts are produced using stainless steel and mild steel to withstand the test of time. Also, they are powder coated to endure dust, harsh chemicals, solvents, and other environmental contaminants.