Versatile Feeder Bowl Systems for Electronic Components

Electronics have formed the foundation of many industrial and commercial products available today. When bulk tier 2 and tier 3 parts are used by manufacturers to produce products and components, it is imperative that only error-free electronic parts are used in the manufacturing process. Vibratory Feeders Inc. (VFI) can help you find compatible parts within minutes with the help of our electrical and electronics feeder bowls.

We can provide custom bowl feeders that have the capability to feed small-sized miniature components as well as medium-sized electrical boxes. Our parts feeding capabilities also include:

- Contacts

- Connectors

- Metal strips

- Commutators

- Electrical Terminals

We can even feed miscellaneous electrical components that do not fall under any specific product category.

VFI Product Solutions

To maintain the VFI standard of excellence, all our vibratory bowl feeder products are manufactured using 11-gauge 304 stainless steel. We can also utilize other materials when producing components used for the handling of fragile parts. For electronic components, we at VFI recommend the following solutions:

- Feeder Bowls:

- Our cascade bowls are designed with inner tracks for easy parts orientation without the hazard of parts getting stuck in between the tracks.

- The tracks are lined with wear-resistant urethane sheets, which allow for quiet operation. We can also use 3M Brushlon material for feeding of oily parts.

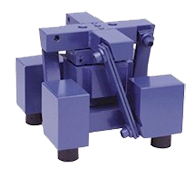

- Drive Units:

- We recommend specially designed pneumatic drive units to support 24″ to 36″ diameter cascade bowls. These are capable of providing 60 vibrations per second along with full wave rectification control.

- Linear Power Tracks:

- We provide linear power tracks that ensure smooth feeding and conveyance of oriented parts from a vibratory bowl feeder to the next processing point.

- Optional jack screws can be provided to customers who wish to install the track in a vertical position.

All VFI products can be custom designed to meet the needs of your manufacturing or processing application. If you would like to know more about our products, please feel free to contact us.