Vibratory Bowl Feeders At A Glance

A vibratory bowl feeder comprises a parts-orienting bowl mounted on a vibrating drive unit with a variable-amplitude controller. The drive unit causes the bowl to vibrate. As a result, parts in the bowl move around a tooled track that sorts and orients the parts per customer specifications. Bowl feeders could either be outside-track or cascade types, and are typically fabricated from #304-stainless steel.

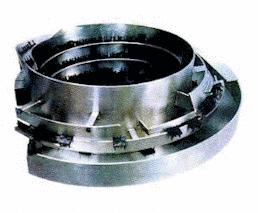

Outside Track Bowl Feeders

This bowl features tracks that are directly above each other. The parts are directed to the outside where there is a long distance for tooling. If you need highly precise part orientation, have high feed rates, or need multiple feed lines, the outside track bowl is recommended. The downward pitch of the outside track allows easy separation and orientation of parts. By tooling on the outside instead of on the inside, parts tend to buckle and fall into the return pan instead of binding.

One of the considerations in determining the size of an outside-track bowl feeders is in the opening in the wall that allows parts that do not feed out of the bowl to return to the inside. Adding a Surlyn coating to the bowl helps mitigate high noise and reduces the amount of grinding and polishing in keeping with FDA mandates.

One of the considerations in determining the size of an outside-track bowl feeders is in the opening in the wall that allows parts that do not feed out of the bowl to return to the inside. Adding a Surlyn coating to the bowl helps mitigate high noise and reduces the amount of grinding and polishing in keeping with FDA mandates.

Cascade Bowl Feeders

The outward spiraling tracks of this bowl type are used for feeding easily-oriented parts such as screws and dowels. These bowls cost less than outside-track designs and are typically quieter in operation. As there are no “over and under” tracks for parts to wedge between, parts not properly oriented are rejected back into the bowl falling only to the lower track.

For FDA code conformance, cascade bowls feeders can be coated with specific materials, or welded and polished according to customers’ requirements. These bowls also lend themselves to lining with sheet urethane for wear and noise abatement and with 3M Brushlon for feeding oily parts.

Regardless of the bowl type, good design for either style bowl includes holes and/or slots to remove dirt and foreign matter.

Part Feeding – Things to Consider

Most parts fed in vibratory bowl feeders are between 3/8 and 1 1/2 inches in their longest dimension, with the practical limits being 1/8 to 8 inches. Feed rates are usually determined by how much bounce a part can take with the feeder still controlling the part. Linear feed rates of the bowl vary between 10 and 30 or more feet per minute. Parts that are small, thin or difficult to orient will feed slower than larger or heavier parts.

If you need an efficient parts handling solution, VFI is just a call or Email away.