Orientation and Feeding of Construction Materials

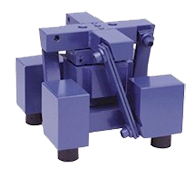

Vibratory Feeders Inc. (VFI) designs and manufacture custom bowl feeders that can meet the strenuous demands of the construction industry. Whether you are using them in the manufacturing facility, or at a construction, our vibratory bowl feeders can be extremely useful in construction applications.

Our construction bowl feeders are designed to support and enhance precise functions in construction applications. Our feeders have the capabilities to provide continuous, efficient performance in harsh environments. The construction feeders can orient and feed diverse parts and objects :

- Mortar

- Cement

- Bricks

- Construction fasteners

- Various types of abrasive materials

Benefits of Using Construction Bowl Feeders

Our automated feeders are designed to provide immense benefits to operations involving construction materials and products:

- Reduced dependence on manual labor

- High efficiency rates

- 24 hour operation

- Faster turnaround time

Our Products and Capabilities

At VFI, we provide complete automated systems as well as single components that can act as pivotal solutions for construction applications. Some of our offerings include:

- Bowl Feeders:

- The cascade bowl feeders can efficiently move and orient small components like screws and bolts, while the outside track bowls can be used for high speed and multiple feeding lines.

- Supply Hoppers:

- Our straight front supply hoppers comprise a wide tray opening, straight front, and large bin opening. This allows for efficient material feeding without the creation of lumps, which can get jammed in the bowl feeder.

- Linear Power Tracks:

- In a manufacturing facility, components such as screws, bolts, threaded inserts, and electric hammer heads can be quickly and easily processed with the help of our linear power tracks.

For construction applications, our vibratory bowl feeders can be designed with both cascade and outside track bowls.

We at VFI recommend our straight front supply hoppers to clients from the construction industry.

Our linear tracks are the perfect solution for handling and transfer of various components.

Customers can choose from standard products or a custom combination to suit their needs. All our products can be customized to meet your specific application requirements. If you would like to know more about our product solutions, please feel free to contact us.