Automated Part Handling System for Metal Work Production

Vibratory feeders have been a boon to the foundry industry. Feeder products from Vibratory Feeders Inc. have been among the solution driven machines that have supported the demand for quality foundry products and cost-effective metalwork production.

Feeder Capabilities

The use of our automated machines has led to a reduction in defective products, manufacturing costs, human injuries, and has increased overall turnaround time. Our feeders are designed and manufactured with high grade 316 stainless steel, which provides advantages of high strength, and improved pitting and corrosion resistance at high temperatures.

We have the capabilities to design high performance, custom feeders for different types of materials and products, such as:

- Steel

- Zinc

- Pipes

- Brass

- Tools

- Aluminum

- Magnesium

- Iron Castings

Product Offerings

We offer the following product solutions to enhance your metal working operations.

- Outside Track Bowl Feeders :

- These are designed for high feed rates as well as multiple feed lines.

- The outside track is pitched downward to allow components to move separately.

- Outside track tooling enhances parts orientation and improves rejection of defective parts.

- Straight Front Supply Hoppers:

- These hoppers consist of wide trays and larger bin openings, which allow for easy component movement.

- The weight of the material being fed should not be more than 30 pounds. We can provide custom models that can handle heavier components.

- These supply hoppers can be mounted on height-adjustable floor pedestals.

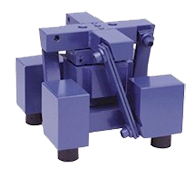

- Drive Units:

- We recommend our drive units that support the 15″ to 30″ core diameter outside track bowls.

- These drive units are AC operated, and provide 120 vibrations per second.

- The units can provide amplitudes ranging from 6 to 15 at 115v.

To ensure the safety of workers as well as equipment, we also provide auxiliary products such as floor stands, protective enclosures, system controls. For more information, please feel free to contact us.