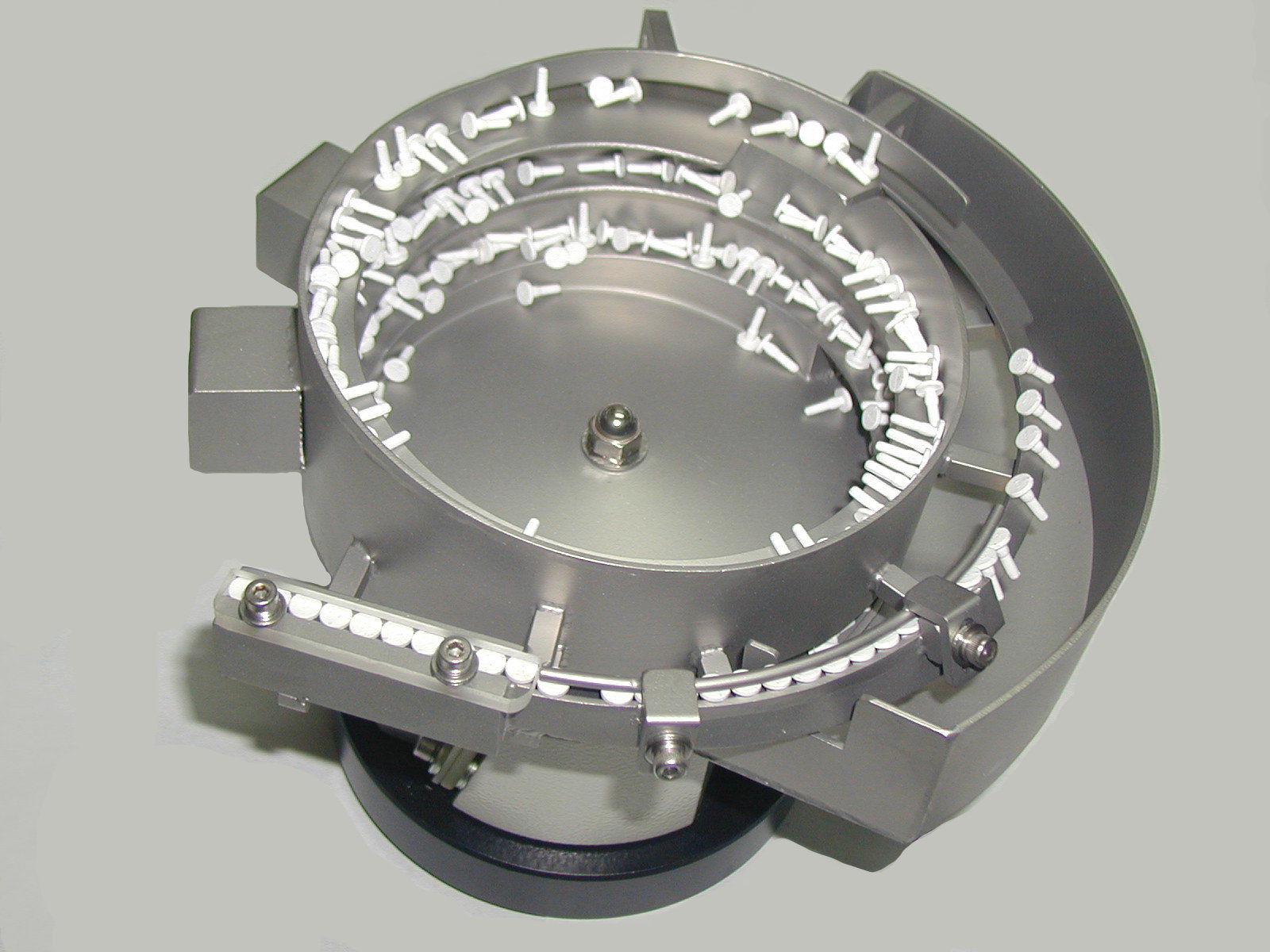

When discussing the topic of equipment maintenance, vibratory feeders are systems that rarely need it. However, this doesn’t mean that they won’t break down at some point due to a problem. As they are automated, and rarely operated with the help of a user, sooner or later, these material handling systems are bound to malfunction/shut down. So we thought we would give you the lowdown about a few common problems associated with vibratory feeders.

Issues Pertaining to Vibratory Feeders

Generally, organizations that use these feeders will find four common problems to deal with. Let us take a look at them and their solutions.

Problem: Noise Emanating from the Feeder: This is possible due to a few reasons – Parts in the bowl are hitting against each other. The stand on which the feeder is placed is not stable enough. The fastener to the unit is not tight enough.

Solutions:

- You can reduce the number of parts in the bowl, or use a supply hopper.

- Brace the open space under the stand to strengthen the base. You can also just replace the stand.

- For the drive unit, disassemble the bowl from the unit. Clean all the surfaces and then reassemble the bowl.

Problem: Feeder Bowl Dead Spots: These are places within the bowl where a lag of activity is taking place, causing an imbalance. Other reasons for dead spots can be – a broken spring, or a cut or loose foot.

Solution: There are three ways to rebalance the feeder:

- Use counter weights to create the balance.

- Adjust the torque on the bottom end of the feeder’s springs.

- If the problem is quite drastic, then change the springs.

These are the first issues generally face by vibratory feeder operators. The remaining two will be discussed in the next post.